3D Laser Cutting

3D Laser Cutting Services

We’re able to provide 3D laser cutting services which is an accurate, flexible and fast method of processing. Design freedom delivered by tube laser cutting allows creativity and facilitates product ingenuity.

Our clients benefit from the versatility of our dedicated tube lasers which provide flexibility in design. Our tube laser technology can reduce production times and processing cost of tubular products compared to traditional techniques.

This uniQue process streamlines operations and consolidates various fabrication steps into one continuous process. Structural joints or tube-to-tube connections can be created with precise angles and arcs that mate together without the need of extra processing.

We look forward to discussing your ideas and how we can provide cutting solutions to work with your designs.

Capability &

Technology

Tube Laser Cutting Capability

Unique Metals Laser have a wide range of capabilities to suit any Laser Cutting applications using this 3D laser cutting technology.

With increasing capability delivered from the world’s most sophisticated computerised technology, this method or processing pipe or RHS is more viable today than ever before as a replacement for other conventional processing methods. Unique Metals Laser’s clients benefit from having access to the most up-to-date laser cutting equipment in Australia. This technology ensures a faster turnaround of jobs with greater accuracy.

Please click the below link for full details of our laser cutting capabilities.

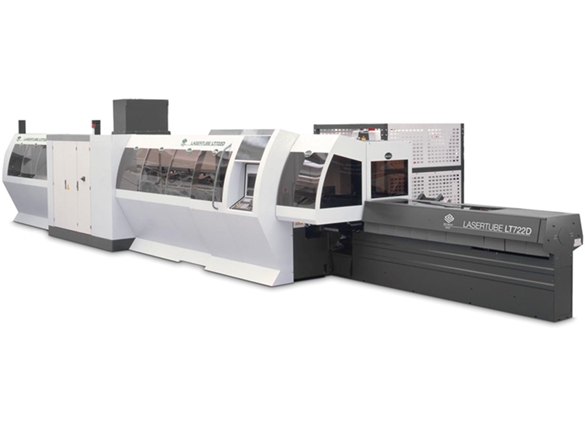

Investing in the best machinery

As with our other laser cutting machinery, Unique Metals Laser has recently installed a state-of-the-art Fibre Laser Cutting Tube Machine incorporating the very latest technology. We can now process longer parts (up to 8m) at faster speeds to meet the requirements of a market sector that is growing as clients develop their products around the versatility of 3D laser cutting tube.